Troubleshooting Common Issues with Membrane Bioreactor Systems

Troubleshooting Common Issues with Membrane Bioreactor Systems

Blog Article

Membrane Layer Bioreactors Described: Efficient Solutions for Clean Water

Membrane layer bioreactors (MBRs) have become an innovative service for attending to the pressing difficulties of wastewater therapy. By integrating biological procedures with innovative membrane filtration, MBRs not only enhance the top quality of treated water but additionally minimize the spatial needs of treatment facilities. As environmental problems magnify, the function of MBR technology in promoting sustainable water management becomes increasingly significant. The intricacies of their procedure, advantages, and prospective applications merit a closer examination to fully recognize their impact on the future of water treatment.

What Are Membrane Layer Bioreactors?

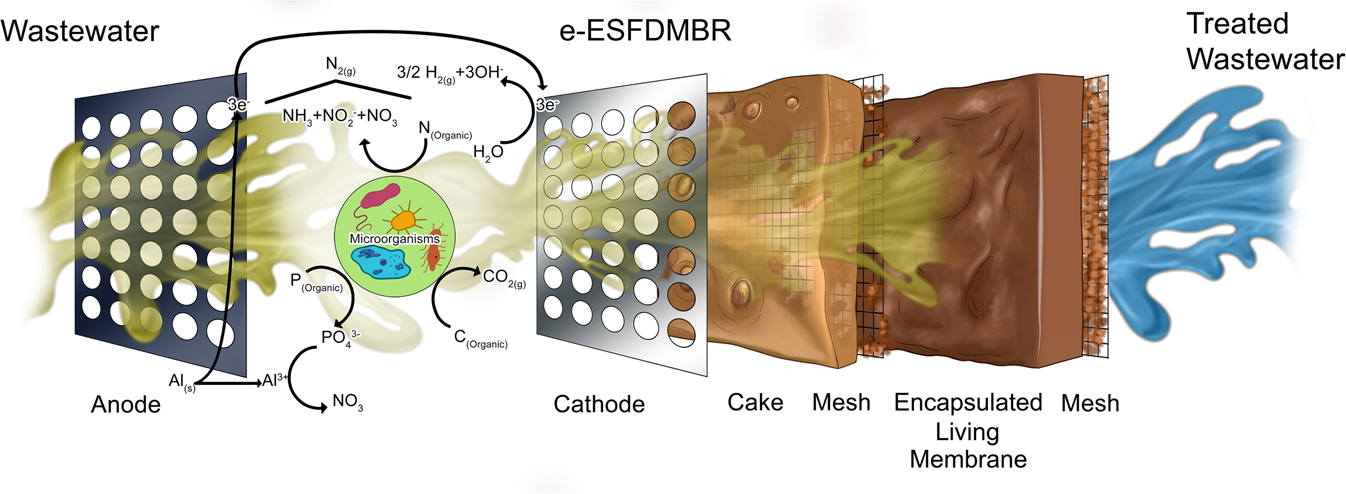

Membrane bioreactors (MBRs) are sophisticated wastewater treatment systems that integrate organic destruction procedures with membrane filtering technology. This integration permits for the effective elimination of contaminants from water, making MBRs a recommended option in numerous applications, including municipal wastewater treatment and industrial effluent monitoring.

One of the crucial advantages of MBRs is their ability to create top notch effluent, frequently suitable for reuse in watering or commercial processes. Furthermore, MBRs need a smaller footprint contrasted to standard therapy systems, making them suitable for city settings where room may be restricted.

Moreover, MBRs can effectively manage varying influent loads and are much less vulnerable to the results of hazardous shocks. These qualities contribute to their expanding appeal as a sustainable service for dealing with the raising demand for clean water while decreasing ecological influences.

How Membrane Bioreactors Job

While the operation of membrane layer bioreactors (MBRs) may seem complicated, it fundamentally rotates around the synergy between biological procedures and membrane purification. MBRs integrate an organic treatment process, generally triggered sludge, with a membrane splitting up system to deal with wastewater successfully.

In an MBR system, wastewater is very first presented into a bioreactor where bacteria deteriorate raw material and various other contaminants. The biological activity lowers the focus of contaminants while advertising the growth of biomass. Following this biological therapy, the combined alcohol is subjected to membrane filtration, which can be microfiltration or ultrafiltration, depending on the preferred effluent top quality.

The membranes function as a physical barrier, permitting water and small solutes to pass while preserving suspended solids and bigger particles. This enables the system to keep a high concentration of biomass within the activator, improving the therapy performance.

Additionally, the constant separation of cured water from the biomass facilitates a portable style and reduces the impact of the therapy facility. On the whole, the combination of organic destruction and membrane filtering in MBRs results in trustworthy and reliable wastewater treatment, guaranteeing top quality effluent ideal for numerous applications.

Benefits of MBR Technology

Among the vital advantages of membrane bioreactor (MBR) innovation is its ability to produce premium effluent with a dramatically reduced footprint contrasted to standard wastewater treatment methods. MBR systems successfully combine organic therapy and membrane layer filtration, resulting in premium elimination of impurities, including put on hold solids, virus, and raw material. This ability leads to effluent that often satisfies or surpasses strict regulative criteria for reuse and discharge.

Furthermore, MBR technology permits for higher biomass concentrations, which enhances the treatment efficiency and reduces the required reactor quantity. This portable layout is specifically helpful in city locations where room is restricted. The functional flexibility of MBR systems likewise suggests they can adjust to differing influent top qualities and flow rates, making them appropriate for a wide variety of applications.

In addition, the minimized sludge manufacturing connected with MBR procedures adds to reduce operational and maintenance costs. The membranes function as a physical obstacle, minimizing the threat of obstructing and enabling longer operational periods in between cleansing. On the whole, the advantages of MBR innovation make it an eye-catching remedy for lasting wastewater treatment, attending to both ecological worries and the need for effective resource administration.

Applications of Membrane Layer Bioreactors

With their adaptability and performance, membrane layer bioreactors (MBRs) locate applications throughout various fields, including local wastewater therapy, industrial procedures, and even water reclamation. In municipal setups, MBRs provide a small remedy for treating wastewater, properly eliminating contaminants while all at once generating high-quality effluent that fulfills stringent governing requirements. This makes them especially suitable for areas with restricted room.

In commercial applications, MBR innovation is made use of for dealing with process water, especially in sectors such as food and beverage, pharmaceuticals, and petrochemicals. These industries profit from MBRs' ability to manage high organic loads and their efficiency in recuperating valuable sources from wastewater, such as nutrients and water.

Furthermore, MBRs play an essential function in water recovery initiatives, making it possible for the reuse of dealt with wastewater for irrigation, industrial procedures, and even as potable water after more therapy (Membrane Bioreactor). Their efficiency in eliminating virus and toxins makes them a reputable option for making certain water high quality in different reuse applications

Future of Water Therapy Solutions

The future of water treatment click here for more services is positioned for transformative developments driven by technical innovation and enhancing environmental awareness. As worldwide water shortage ends up being a pressing concern, brand-new methods, including membrane layer bioreactor (MBR) systems, are established to play a pivotal function in improving the performance and sustainability of water therapy processes.

Arising modern technologies such as expert system and artificial intelligence are anticipated to enhance therapy operations, permitting real-time tracking and anticipating upkeep. This will boost the general dependability and performance of water therapy centers. Moreover, improvements in membrane materials, such as graphene and nanofiltration, promise to increase permeation prices and minimize fouling, resulting in reduced energy intake and operational costs.

Furthermore, the integration of renewable resource sources into water therapy plants will add to greener methods. The round economic situation version will also obtain traction, encouraging the recovery content of valuable resources from wastewater, such as nutrients and energy.

Final Thought

Membrane bioreactors (MBRs) have emerged as an advanced option for attending to the pressing obstacles of wastewater therapy. By incorporating organic procedures with read this post here advanced membrane layer filtering, MBRs not just enhance the high quality of cured water yet also minimize the spatial requirements of therapy centers.One of the vital advantages of membrane layer bioreactor (MBR) innovation is its capacity to produce top quality effluent with a dramatically reduced impact compared to standard wastewater treatment techniques.With their convenience and efficiency, membrane layer bioreactors (MBRs) find applications across numerous industries, including local wastewater therapy, industrial processes, and even water improvement.In conclusion, membrane bioreactors represent a significant improvement in wastewater therapy modern technology, integrating biological procedures with reliable membrane filtration to produce top notch effluent.

Report this page